Twenty-first Century Irrigation... What is it?

Golf course irrigation systems consist of three major infrastructure components. At Stowe Country Club, we recently completed an overhaul and upgrade of one of these components; the control system. The pumping system and the delivery system are the other two. The means to deliver water to the turf is one of the most valuable tools a golf course has. The superintendent is responsible for managing water usage to yield optimal conditions of playing surfaces. Executing this simple principle requires that the superintendent relies on all three major components to be flawlessly operable.

A basic approach to appropriate watering practices is simply to not over-water. This is done for many reasons that include playing conditions, disease management, resource conservation, and more. It is crucial that watering occurs only when necessary and not only when convenient. This brings to light the importance of the system and its components to be functional during crucial demand periods.

The irrigation system that is in use at Stowe Country Club is over twenty-five years old which poses great concern for possible failure. We had the opportunity to upgrade the control portion of the system this summer. This is essentially the brain of the system and consists of a series of electrical field controllers that transmit electricity to each of the hundreds of sprinkler valves throughout the golf course to deliver water. Using the seven former field controllers at SCC as stand-alone programmable controllers is an example of the most basic application of automated irrigation. Until a week ago our assistant superintendent, Matt Jung, would make a visit to each field controller nearly every day and manually program the watering schedule. This is analogous to setting 168 alarm clocks each evening but they cannot all go off at once, they have to be spread apart so as not to get so loud it wakes the neighbors.

Previous stand-alone controller on hole 10

Installation in progress

Newly installed controller with new concrete pad and surge grounding

The pumping system has a maximum supply threshold of delivering 450 gallons per minute (GPM). If there is too much overlap in the number of open valves that are demanding water during the nightly watering schedule, an alarm is activated and the pumps shut off before they are damaged. The pumps will live to see another day but the irrigation schedule that was interrupted is now incomplete. Most full watering cycles take 5-10 hours to run which is why an automated night time schedule is the only feasible run time.

The control system that we installed this July incorporates a central controller in the form of a computer that communicates to each of the seven new field controllers via radio frequency. The central computer uses smart technology to schedule and facilitate the automated watering. The central component creates a cycle schedule based on our daily parameters that maximizes the efficiency of the pumping system and its electricity consumption. It monitors theoretical GPM flow in real time and adjusts watering in the field to consolidate running time while also avoiding overuse of the pumps.

burying surge grounding rod

Previous controller on hole 1 in area of play.

Newly located controller site out of play.

(We anticipated this relocation and dropped a sleeve tube

underground to run wires through prior to cart path paving in May.)

The entire irrigation system benefits from this technology. Knowing that all three major system components are aging and their reliability is questionable, we concluded that the smart features of the central control will help preserve the longevity of the system as a whole. By prioritizing the control system upgrade we can confidently rely on the pumps to run at a more consistent speed or RPM, reducing wear and tear and reducing run time hours. By maintaining a constant pumping speed and maximizing the demand of the available GPM flow, our underground piping system is moving a more steady flow and a holding a more static pressure level. Without central monitoring, water flow in the underground pipe can be variable and sporadic and can cause stress fractures and catastrophic breaks, especially in 25 year old PVC pipe.

Left: the central control computer set up in the maintenance office.

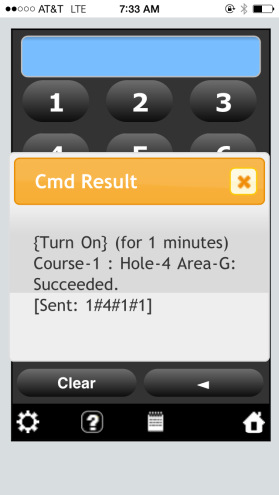

Right: a screenshot of my cell phone utilizing an app that can communicate

with the central control computer remotely.

The control system is up and running and programming is as simple as a mouse click or as complex as we can fathom. In an industry where water is a diminishing resource in some regions, it is our responsibility as superintendents to be conservative, efficient, and accurate in our watering practices. There is an endless amount of data that we have begun uploading to our central control that will make our system operate optimally. As we build our database we will begin to employ features of the control that communicate with our weather station to maximize water use efficiency. For example, the watering schedule can be set to pause or end at the detection of rain. The weather station will also feed data that measures the amount of evapotranspiration (plant moisture loss during day) and determine the amount of irrigation to apply to replenish vapor loss. These are good examples of technology opening up a whole realm of new ways to increase accuracy and efficiency. Not to mention, the ability to operate the sprinklers on the golf course remotely from anywhere in the world with our cell phones!

Mark Finch, Golf Course Superintendent